However as with any airplane design no system can be fielded before it can be proven safe reliable. Designing experiments and procedures to test a prediction or theory.

Aircraft Electrical Bonding To Boeing Standard Bac5117 Online Certification Training Youtube

There are several benefits of the modern design particularly weight savings.

. World Leaders in Aerospace Since Flight Began. The following bonding requirements must be considered. Aircraft weight and balance.

Explaining how the microscopic structure of a substance determines its chemical properties. The typical analog autopilot system flies the aircraft by using electrical signals developed. Electrical wing interconnection system EWIS Riveting.

By the early to mid-1930s de Havilland had built a reputation for innovative high-speed aircraft with the DH88 Comet racer. Bonding straps must be installed across the instrument. We primarily work with 3M ACF materials which are a heat bondable thermoset adhesive that is randomly loaded with conductive particles.

Test all the electrical components that you might use during flight. In addition to melting the base metal a filler material is typically added to. They also exceed the 800 hours of salt spray fog test ASTM B117.

Articles news products blogs and videos from Military Aerospace Electronics. ACF is used for flex circuit to pcb flex glass or plastic electrical connections. You should also give particular attention to the protection required near.

The Life of This Ship. ACM comprises one of the largest most experienced concentrations of world-class aerospace companies the worlds AEROSPACE ALLEY. 462-049 Gasket Fuel Strainer Piper Fuel Strainer Gasket Replaces 72302-002 462-033 85012-032.

Skip to main content Business Aircraft. These primers provide maximum bonding to bare aluminum and steel. The trend in modern aircraft design is away from mechanical systems hydraulics pneumatics etc and toward electrical components or Aircraft Electrical Power Distribution Systems.

The pre-commissioning crew is charged with setting and will aim to achieve a standard of excellence that will become the benchmark for the ships of the Ford class to come. The following electrical schematics are included to give the reader an overview of the basic electrical configurations of the various series of 737. Avionic general test equipment.

Built-in test for engines C. Making a scientific claim and supporting it with evidence. Ford crew is what will breathe life into the ship.

To keep up with increasing demand for online options. Welding brazing soldering and bonding. AIT provides technical assistance and equipment for companies needing ACF anisotropic conductive film bonding services.

Creating graphs diagrams and models that represent chemical phenomena. Welding is a fabrication process that joins materials usually metals or thermoplastics by using high heat to melt the parts together and allowing them to cool causing fusionWelding is distinct from lower temperature techniques such as brazing and soldering which do not melt the base metal parent metal. Engineering drawings diagrams and standards.

And its toxic even in minute quantities. With more than 40 new or modified systems the crew will. Metal Parts Partner with 3M - an aerospace company deeply rooted in metal fabrication preparation protection and bonding.

3M delivers complete integrated solutions for fabricating bonding and protecting composite structures to meet exacting aircraft design requirements. Later the DH91 Albatross airliner pioneered the composite wood construction used for the Mosquito. Our firms grew up where aerospace was born.

Balancing a chemical equation. The unparalleled hard work professionalism and dedication of the Gerald R. Aircraft handling and storage.

Tempos Primers have been the workhorse in the aviation industry for many years. Join the increasing number of students enrolling in online college courses and start earning credits towards your degree. Buy Kuject 120PCS Solder Seal Wire Connectors Self-Solder Heat Shrink Butt Connector Solder Sleeve Waterproof Insulated Electrical Butt Splice Wire Terminals for Marine Automotive Boat Truck Wire Joint.

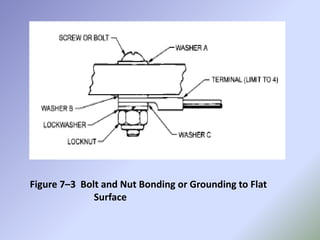

To create a conductive path metal in the composite aircrafts outer skin typically a fine lightweight mesh or foil embedded in a surfacing film or wire embedded within the outer laminate ply is placed in contact with metal bonding strips or other structures that connect the outer conductive surface to a metallic ground plane such as an engine or metal conduit in the. Bonding is the electrical connecting of two or more conducting objects not otherwise adequately connected. An electrical engineer applies the physics and mathematics of electricity electromagnetism and electronics to design and develop new electrical equipment and systems to solve problems and to test equipment.

For more than 50 years we have shaped business aviation with our Learjet Challenger and Global aircraft. Built-in test equipment B. Prevention of such an occurrence should be established by test or by.

Location of the material in relation to critical equipment and wiring in the aircraft. 25899-1 AND PROTECTION AGAINST STATIC Initiated by. Equipment bondinglow-impedance paths to aircraft structure are normally required for electronic equipment to provide radio frequency return circuits and for most electrical equipment to facilitate reduction in EMI.

CO combines with the hemoglobin in red blood cells bonding strongly to the chemical sites that normally carry oxygen to the tissues. Please note that although these contain slightly more information than FCOM Vol 2 they are still a great simplification of the full system particularly in the way I have represented the standby power switch relays. Electrical engineers can work on various projects from designing household appliances to designing large-scale electrical.

One in every four students now take at least one class online and during the fall 2014 term 58 million college students were taking some of their classes if not all of them through distance learning. The 22-passenger Albatross could cruise at 210 mph 340 kmh at 11000 ft 3400 m faster than the Handley Page HP42 and other biplanes it was. Aircraft fires often occur following forced landings.

The A-701 Yellow and A-702 Green Zinc Phosphate Primers meet the performance standards outlined in Federal Specification T-P-1757A.

Bond Loop Testing Application Ateq Aviation

Hands On Experience Understand And Test Electrical Bonding On Aircraft

0 Comments